Development of Screen-Printable Cu Paste

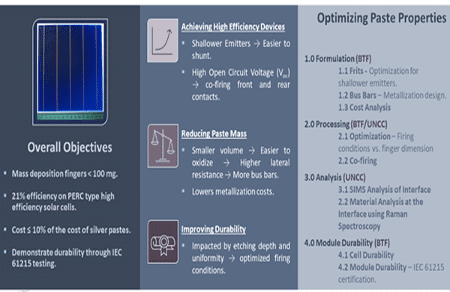

Dr. Abasifreke Ebong, Professor of Electrical and Computer Engineering, has received funding sponsored by Bert Thin Films LLC as a part of the Department of Energy (DoE) Solar Energy Technology Office (SETO) for a total of $250,000 for two years. Dr. Richard Stephenson at Silicon Valley Materials Technology (co-PI) and Dr. Dana Hankey at ACI (Co-PI) are the Co-PIs. As the DOE seeks to cut the cost of solar cell metallization in half by 2030 an approach to use Cu, which conductivity is slightly lower than the state-of-the-art silver, is proposed. The cost of Cu is 1/100 that of Ag, thus, makes economic sense in investigating the replacement of Ag with the alternative low-cost. The solar cell industry uses the high-throughput fire-through-contact methodology, and the Cu alternative proposed here will follow suit without adding any other costs. The two issues with Cu that would be overcome to be successful is the oxidation of Cu in the atmosphere and diffusion of the same into silicon material at elevated temperature. So far, the results of the cells obtained are positive because we are able to make excellent contacts without shunting solar cells. The preliminary results show an efficiency of 90% to the state-of-the-art Ag contacts to the PERC solar cell architecture. This work is carried out through effective collaboration with Bert Thin Films LLC in Louisville, Kentucky which specializes in paste formulation, and UNC Charlotte which specializes in solar cell fabrication and understanding of metallization. Graduate students are doing their research to understand the impact of various materials in preventing the oxidation of Cu in the atmosphere and sequestration of Cu in the reformed glass after high-temperature sintering to prevent the diffusion of Cu into silicon. The expected outcome is the fabrication of stabilized silicon solar cells with PERC architecture of efficiency identical to the state-of-the-art Ag metallization.