Low-cost Silicon Solar Cells

Improvement of screen-printable metallization paste for low-cost silicon solar cells utilizing silver coated copper powders

Dr. Aba Ebong

Dr. Abasifreke Ebong, Professor of Electrical and Computer Engineering, has received funding through a collaboration award to Dr. Richard Stephenson at Silicon Valley Materials Technology (co-PI) and Dr. Dana Hankey at ACI (Co-PI) from the Department of Energy (DoE) Solar Energy Technology Office (SETO) for developing low-cost solar cells. The grant has a duration of 3 years with a total funding of $1,600,000.00 (UNC Charlotte portion: $561,995.00).

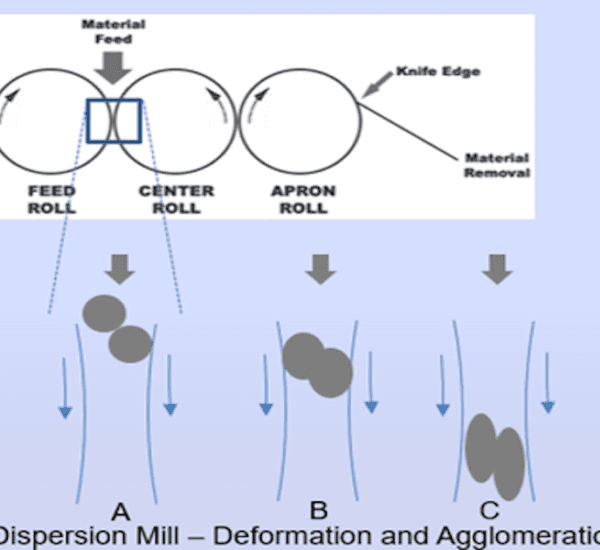

Metallization is one of the major costs associated with electricity generated by photovoltaic cells. Current industrial practices, the baseline technology, addresses cost in various ways with the objective of reduction in the total amount of metallization weight used per cell, namely silver (Ag). The approach is through fine gridline design and use of multi-bus-bars metallization architecture. Screen-printing of Ag in the form of a metallization paste is the major industrial-state-of-the-art metallization technology for the solar cell industry and it is critical to either replace the Ag metallization or replace part of the Ag with another metallization material. The proposal focuses on the of utilization Ag coated Cu powders (Ag|Cu) to create metallization paste to replace the current industrial Ag paste state-of-the-art cost effectively. This will provide an industrially scalable paste processing technique to yield superior characteristic pastes for PV metallization through the use of cavitation technology. A major goal of this work is to provide an industrial solution to maintain the current industrial manufacturing processing steps. The objective is to attain equivalent or better conversion efficiency at significant cost reduction of metallization and cell fabrication through significant material cost reduction. Cost modeling shows module fabrication will decrease the balance of system (BOS) cost and lead to DOE’s 2030 goal of 3¢ LCOE (from current cost per wafer of ~0.707¢ to ~0.010¢)